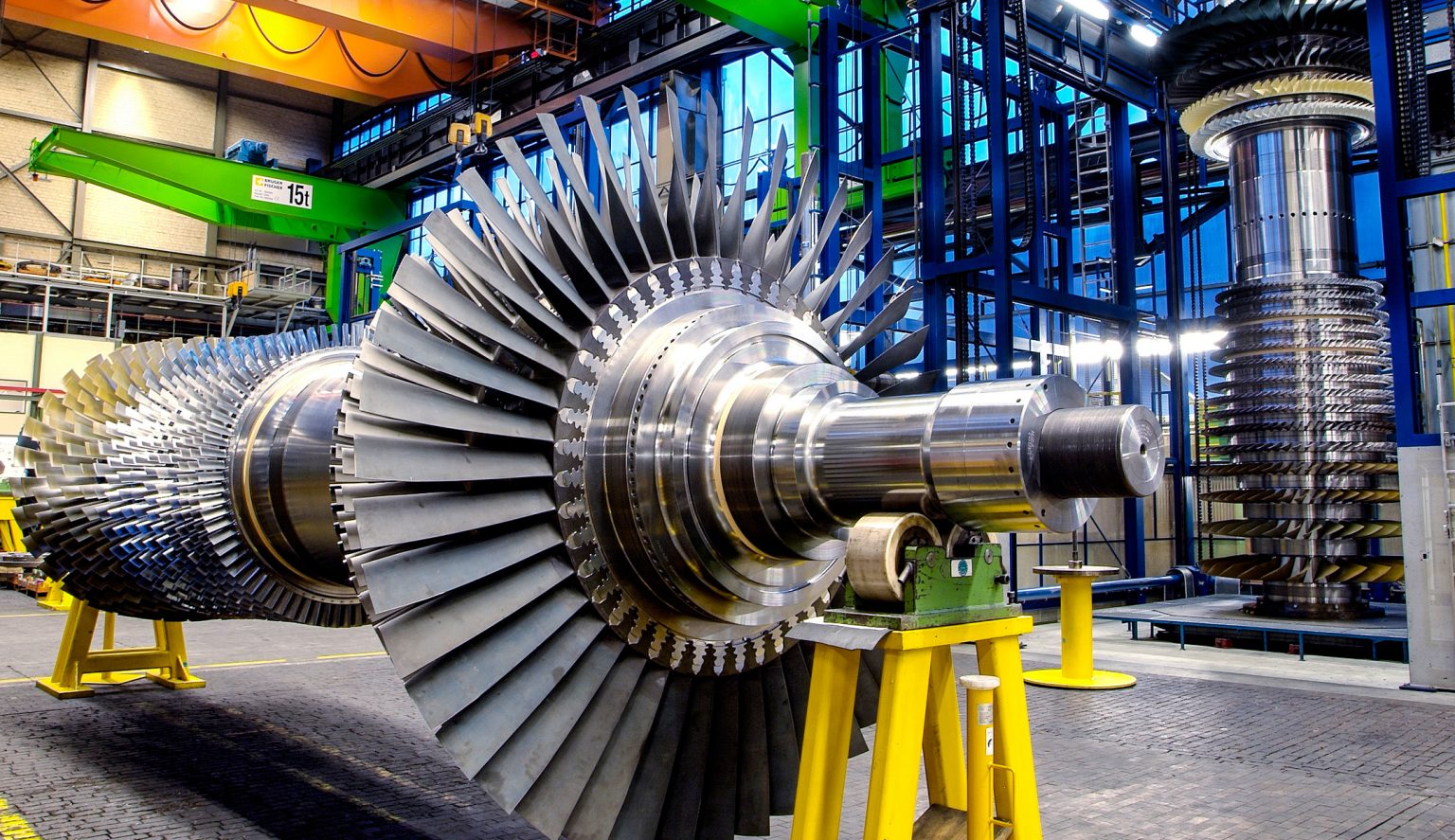

gAS TURBINE

Plate Heat Exchanger Applications in Energy Production with Gas Turbines

The efficiency of electricity generation in gas turbine power plants, whether in simple cycle or combined cycle configurations, varies depending on the cooling method of the plant.

Gas turbine power plants located in areas with a water source use either direct cooling or indirect cooling with a cooling tower.

In the direct cooling method, water taken from a nearby water source is sent to the plate heat exchanger units present in the plant. This water is used for gas turbine air cooling, generator cooling, turbine oil cooling, and condenser cooling (in combined cycle). After cooling, the water is returned to the same source but at a point away from the intake.

In indirect cooling, the closed-loop circulating water is cooled by a cooling tower through a plate heat exchanger. Additionally, plate heat exchangers are used in various heating processes in power plants, such as condensate heat recovery exchangers, NOX water heating exchangers, and many others.

Gas turbine power plants located in areas with a water source use either direct cooling or indirect cooling with a cooling tower.

In the direct cooling method, water taken from a nearby water source is sent to the plate heat exchanger units present in the plant. This water is used for gas turbine air cooling, generator cooling, turbine oil cooling, and condenser cooling (in combined cycle). After cooling, the water is returned to the same source but at a point away from the intake.

In indirect cooling, the closed-loop circulating water is cooled by a cooling tower through a plate heat exchanger. Additionally, plate heat exchangers are used in various heating processes in power plants, such as condensate heat recovery exchangers, NOX water heating exchangers, and many others.